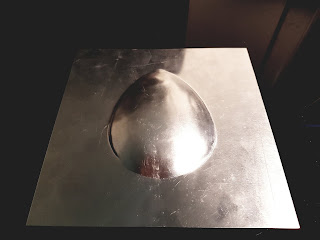

Assignment 3: Reflection

Assignment 3: Reflection Throughout this semester i have really enjoyed this course, learning how to shape metal and the processes that went along with it. While the course was very different to what i expected, i learnt a lot of interesting knowledge and skills. Probably my favorite aspect of the course is having a tangible finished project at the end, especially after assignment one. Studying Landscape Architecture is enjoyable, however design assignments are never more than conceptual, and will never be actually implemented. Thus holding a finished project is a very satisfying feeling. Finished Bowl In assignment two, we had to really consider how to get the desired form, which was challenging as in my studios i am designing a finished landscape, and usually don't put much thought into how it will be built. This challenge really altered my design process, and i think in the future i will be much more aware of how something i design will be made, and whether it